The Dangers of DIY Electrical Repair

There are over 200,000 electricians in the US, so there’s no need to perform your own electrical repair. Plenty of homeowners love taking matters into their own hands when it comes to repairing and replacing aspects of their houses. When you’re dealing with light carpentry, painting, and building things, it can be highly rewarding. When you’re […]

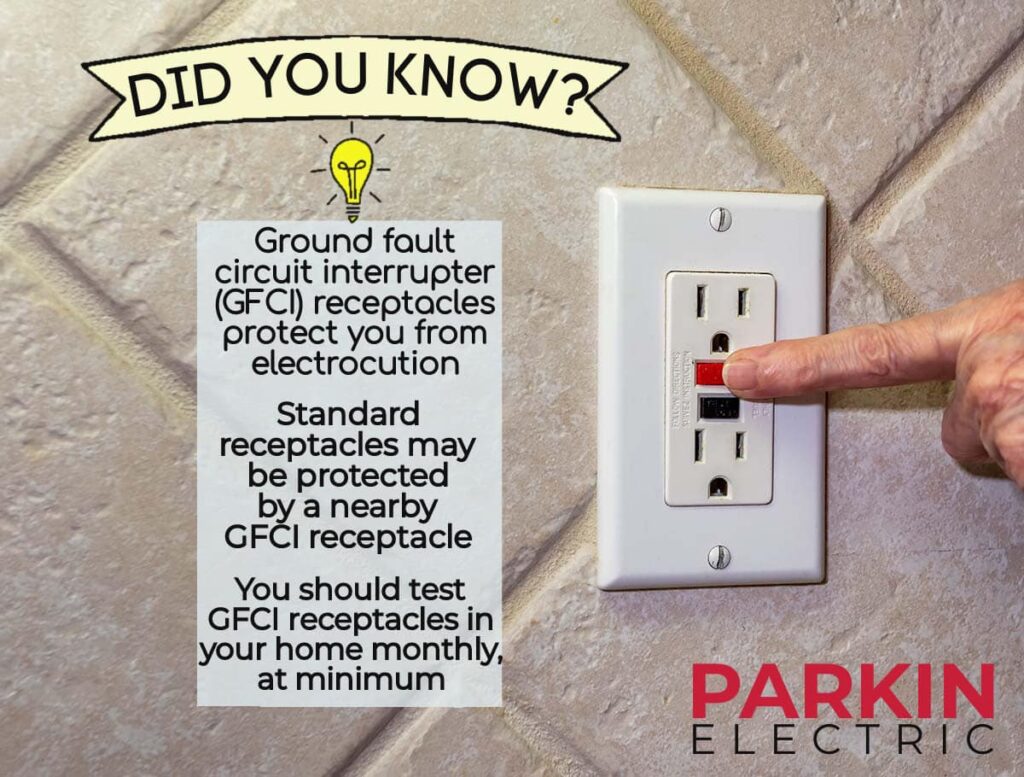

Did You Know? – Ground Fault Circuit Interrupter

Did you know? You probably recognize this outlet, with buttons that say “test” and “reset” on the front. Ground fault circuit interrupter (GFCI) receptacles were invented in 1961, and first required in home applications by the 1971 National Electrical Code. Since then, electrocutions, electrical house fires, and other electrical safety incidents have been reduced by […]

Testimonials

Take a look at what our clients have to say about our services.